Transport systems

inTEC transport systems offer flexible solutions: We have loading and unloading stations, roller transport systems, bespoke chain conveyors and traverse carriages that move lengthwise and widthwise.

︽ Loading and unloading stations

Loading and unloading stations

An overhead crane or forklift is used to place, align and pre-sort the material on the traverse transport fields, and to automatically or manually feed it into the coating system.

Throughput time and manpower is noticeably reduced as a result.

The traverse transport system at inTEC uses hydraulic lifting equipment that can be controlled separately for each lifting table in a group. The lifting tables are then raised together.

We can supply both manual and automated loading and unloading systems.

︽ Rollers

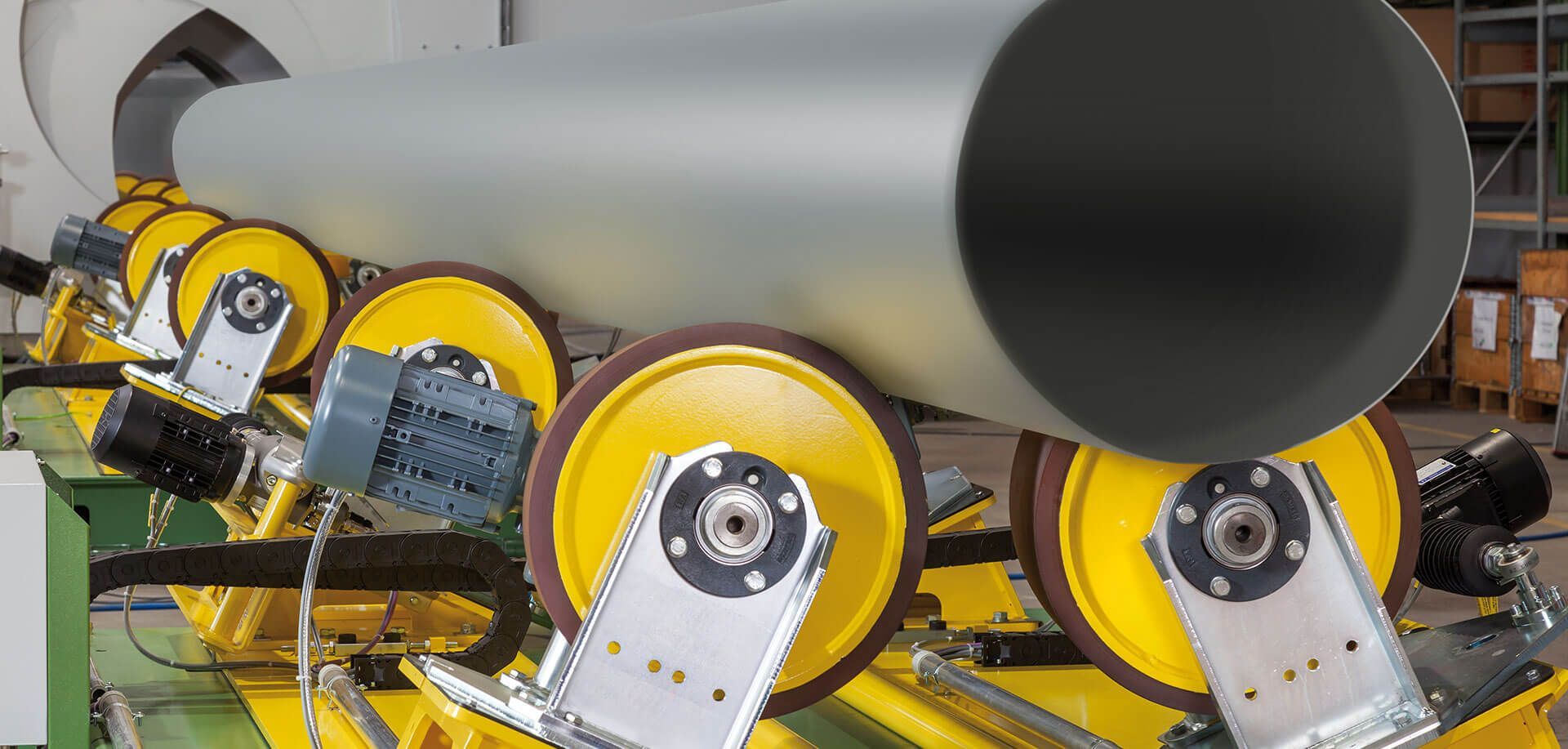

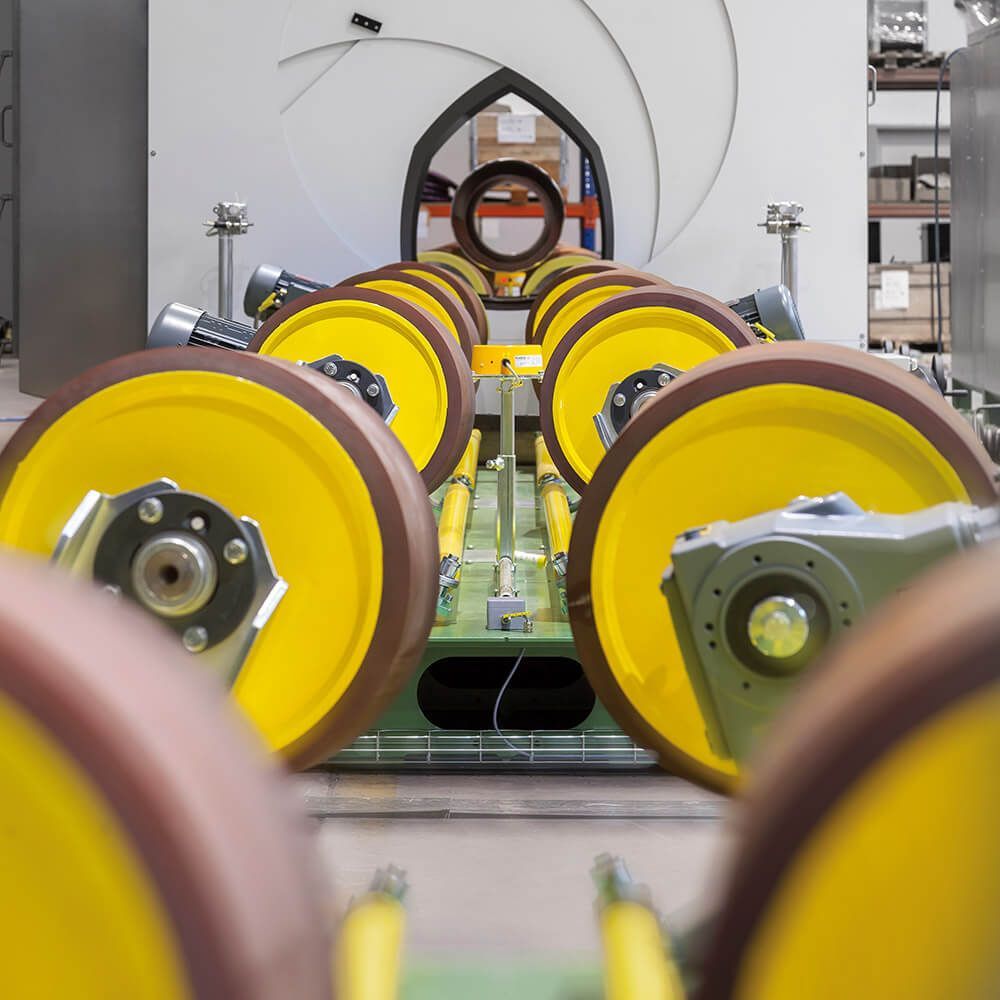

Rollers

Rollers are suitable for use in applications at high temperatures up to 450°C in areas at risk of explosion and in applications involving a greater quantity of contaminants.

Moveable rollers to support short material when being transferred to subsequent transport systems.

Rollers for the transport of pipes.

Videos:

Moveable rollers

︽ Chain conveyors

Chain conveyors

Chain conveyors are designed, produced and combined according to their intended purpose.

Depending on the goods, the chain conveyors are equipped with two or more synchronous chains.

︽ Traverse carriage

Traverse carriage

Traverse carriages to transport material between production lines or within production lines are available for lengthwise and widthwise applications.

They can be moved manually using a control panel or automatically.